Connection and testing of eHouse LAN CommManager , LevelManager controllers using the Debug/Evaluation Module

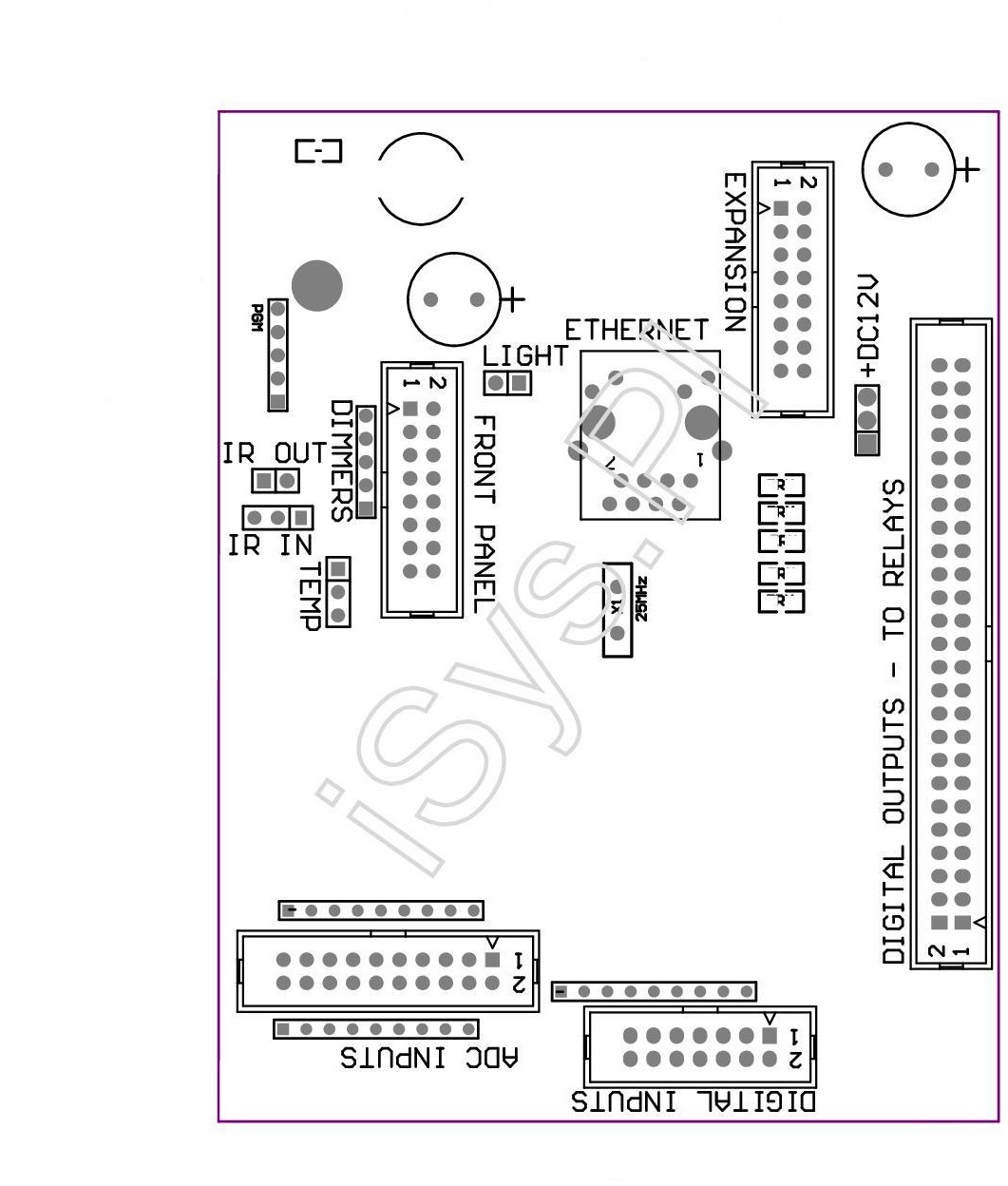

Ethernet Smart home demonstration module allows testing and evaluation of all eHouse LAN smart home controllers.

Evaluation Module is eHouse intelligent building have all hardware resources stored on one PCB replacing production facility at home. Connecting the demonstration to the controller is very simple and requires only the connection of relevant “tapes” between the microprocessor controller and the demo board.

Ethernet smart home controllers can be divided into two basic hardware options :

- mid-range controllers – based on EthernetRoomManager PCB

- large-range controllers – based on CommManager / LevelManager PCB

In this post we will discuss testing, education and evaluation (controllers based on CommManager/LevelManager ) using Ehouse4Ethernet DEMO module.

At the beginning, make sure that the power module is disconnected from demo and CM/LM has removed all cables and connectors.

Remove all cables between CM and Demo. REMOVE the jumpers “ERM Power” the connector s18,s17.

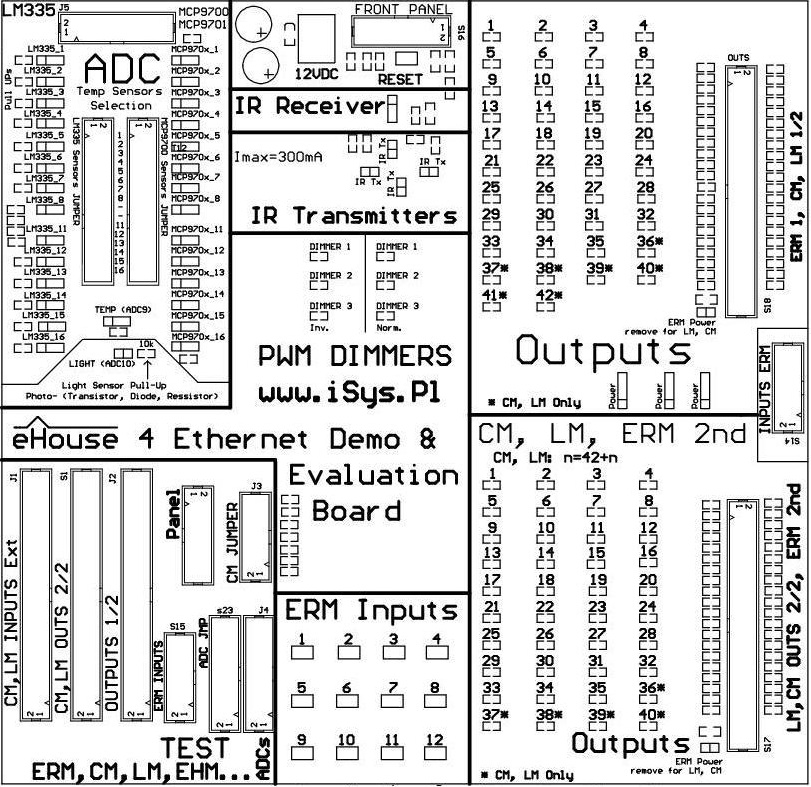

To fully analyze behavior of eHouse LAN smart home controller must be connected to the following CM connectors between DEMO modules and CM/LM :

- Remove all cables from the connectors in “TEST” section

- flat tape 50 pin for outputs ( S18 ) . REMOVE the jumper “ERM Power” the connector s18

- flat tape 50 pin for outputs ( S17 ) . REMOVE the jumper “ERM Power” the connector s17

- flat tape 14pin to 50pin conversion for inputs ( S14 ) .

- flat tape 20 pin ( J5 ) for Analog/digital converters

- 4 pin power supply connection

The next step is the appropriate combination of sensors connected to the inputs of the A / D converter .

Light sensor is related to the temperature sensor selection jumpers , which in the case of connecting light sensor require removal of jumpers for input 10 on both 32-pin connectors .

If we are dealing with a controller other than ERM and we need to input A/D converter connected temperature sensor MCP970x :

- disconnect the jumper ” Light ”

- disconnect the jumper for input 10 on the connector 32 pin for LM335

- short the jumper for input 10 on the connector 32 pin for MCP970x

The next step is for configuration the remaining temperature sensors, connecting them to the required inputs.

They are used for the 2 x 32 pin, allowing the individual connection of LM335 or MCP970x sensors to any measurement input.

You can select only one sensor type.

Activation of the LM335 sensor also provides connecting a resistor (pull Up ) to +3.3V which provides power to temp sensor.

This is a much more secure connection of the sensor than full-powered sensor, because short pin sensor does not cause a short-circuit power supply of controller.

LM335 Sensors , however, in the case of Ethernet controllers do not have a full scale measurement, and measure the temperature to about 56 degrees C. In the case of very low temperatures may also be the effect of the thermometer by self heating itself too much from power current , because these sensors are working optimally for 5V supply voltages .

For example:

To connect the sensor to the input of LM335 No. 7: in 32 -pin connectors remove the jumper in row 7 for MCP970x and short circuit for the LM335.

To connect the sensor to the input MCP970x No. 6: should be in 32 -pin connectors remove the jumper in row 7 for LM335 and short circuit for MCP970x .

Please be aware that depending on the type of controller (kind of PCB hardware and interconnection module) of the inputs can be connected on PCB. Please refer to the detailed documentation of the controller, that measuring inputs are not physically connected to other resources.

The next step is to connect the Ethernet controller to the Router or Switch with a LAN RJ-45 standard cable.

After checking and verifying that all cables are correctly connected and tightened, 12VDC power supply can be connected to the module board demo which is also the power supply for the controller.

Testing of Digital Outputs

Digital output states are displayed on the LED in ” OUTPUTS ” section on evaluation unit .

LED lights for the corresponding output means its ON and turn on relay in the production installation.

The Ethernet controllers digital inputs are connected through resistors “pull Up” to power supply of the controller (3.3V).

To activate them you need to short the input to ground. Due to this, control event for smart home system can come from different sources , mono-stable switches are used (Ring) .

This prevents events collisions when such switch forces input active all the time.

The inputs are connected directly on the module DEMO to switches (micro switch) Located in the “ERM Inputs” section.

Pressing the switch on the module demo is deemed to press the switch in production installation or activation of the sensor connected to the input.

Normally for CommManager, input state should be negated in the CommManagerCfg.exe configuration application by setting the flag “Invert”, because most alarm sensors have NC (normally closed) contacts.

This option should be used only in the case of switches with normally closed contacts NC (normally connected) .

This may relate for example to the reed confirming the closing of windows, doors, gates , blinds or alarm sensors where typical relay/switch outputs are normally connected.

Misuse of options “Invert” the input configuration in relation to the type of switch will cause the automatic start of the event associated with the input for each controller on or reset. In addition, the normal switches will respond with a delay, ie. on letting go of the switch except pressing them.

The next step is to link system events associated with digital input.

This is done in CommManagerCfg.exe application by selecting an event from the list of available events for the controller.

In the case of single input control to select an event “toggle” (change) for output, every time you press the switch status of output changes (invert).

You can also run “output programs” instead of control a single output. The program integrates any combination of the digital outputs (ON , OFF or leave unchanged) .

This will allow the control of such complex scenes consisting of a few/several independent lighting circuits with a few switches.

After configuring the digital inputs, press “Save Settings” on main form of application to load the settings to the controller.

Testing of measurement inputs

After connecting and configuring the analog/digital converter inputs on module demo , which was discussed at the beginning of this post ,proper sensor type must be set in the application configuration CommManagerCfg.exe.

Otherwise, the sensor values will be incorrectly calculated in the control software, panels and thresholds for events execution (for example, temperature) – running events will not make sense.

To change the type of sensor it is necessary to select “Advanced Settings” on main form.

To test exceeds the thresholds (min , max) for a given input of A/D converter , it is necessary to link the relevant events (min , max) in the application CommManagerCfg.exe.

Most common is the incorporation of one of the output (to which the production installation is connected regulating element e.g. heater , radiator valve , underfloor heating valve in the room , etc. . ). For the threshold ( low ) enabling (ON) and disabling (OFF) in the case of threshold ( max) . This will allow you to achieve automatic adjustment of physically measured value ( eg. temperature ) and keeping it in the range ( min , max) with a heater.

It should also be noted , that the threshold settings for all measuring inputs are grouped into programs of the A/D Converters “ADC Settings”.

ADC Programs integrate automated control and heating control , lighting , humidity , etc. .

Active thresholds levels are taken from recently executed ADC program.

After configuring the settings, enter, measurement thresholds of ADC, and programs loaded into the controller, so you should also run the program properly configured A/D converters .

eHouse 4 Ethernet Smart Home Documentation – Technical

eHouse LAN smart home – drives, alarm system

smart home – apartments, flats controller